Woven vs Non Woven Geotextile Fabric: What’s The Difference?

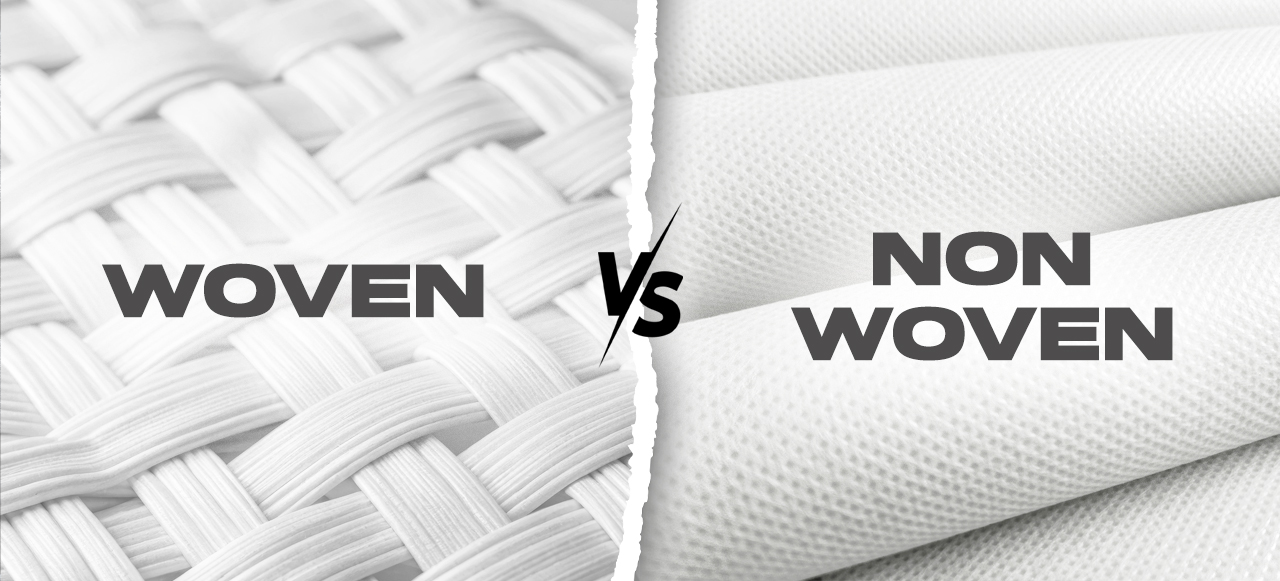

When comparing woven vs non-woven geotextile fabric, it’s important to understand their unique properties and applications.

What is the difference between these two materials? Below, we break down their key differences and best uses.

Both are critical in construction, erosion control, and roadwork, but selecting the right one depends on your specific project requirements.

What is the difference between woven and non-woven geotextile fabric?

The main difference between non-woven and woven geotextile fabric is their construction and purpose. Woven geotextiles are made by weaving synthetic fibers, providing high strength for soil stabilization and load distribution. Non-woven geotextiles are made by bonding fibers together, offering better permeability for drainage and filtration applications.

Woven geotextiles are high-strength, low-stretch fabrics designed for reinforcing roads, stabilizing soil, and preventing erosion. Their interlaced fiber construction makes them highly resistant to stretching, making them ideal for projects where structural support is the priority. However, they have low water permeability, making them less effective for applications requiring drainage.

Non-woven geotextiles, in contrast, have a porous, felt-like structure, allowing water to pass through easily. This makes them the preferred choice for drainage, filtration, and sediment control in projects like landfills, subsurface drainage systems, and erosion control. While they lack the tensile strength of woven geotextiles, they provide excellent moisture management and adaptability.

Choosing the right geotextile fabric depends on your project needs—woven geotextiles excel in structural reinforcement, while non-woven geotextiles are best for water management and filtration.

Ensure your project’s success with the right materials. Contact us to discuss your geotextile fabric needs.

Woven vs non-woven geotextile fabric: A deeper look

So, what is geotextile fabric used for? These fabrics are critical in construction, erosion control, and drainage solutions.

Among the various types of geotextiles, woven options offer high strength for stabilization, while non-woven varieties provide better permeability for filtration and water management.

The table below breaks down the major differences between woven and non-woven geotextile fabric, helping you determine the best fit for your specific application.

| Feature | Woven Geotextile | Non-Woven Geotextile |

|---|---|---|

| Material Composition | Made using slit-film polypropylene or polyester yarns | Made using polyester or polypropylene fibers bonded together |

| Manufacturing Process | Manufactured by weaving synthetic fibers into a strong, grid-like structure | Manufactured using needle-punching, thermal bonding, or chemical processes |

| Strength & Durability | High tensile strength, durable under heavy loads | Lower tensile strength, but still durable for separation applications |

| Water Permeability | Low permeability, limits water flow | High permeability, allows water to pass through easily |

| Primary Use | Generally used for soil stabilization and load distribution | Primarily used for drainage, filtration, and erosion control |

| Flexibility | Stiff, less flexible compared to non-wovens | Soft, flexible, and easier to conform to uneven surfaces |

| UV Resistance | Higher UV resistance due to tightly woven fibers | Lower UV resistance, may degrade faster under direct sunlight |

| Resistance to Puncture | More resistant to puncture due to rigid structure | Less resistant to puncture but provides better adaptability |

| Filtration & Drainage | Limited filtration ability, mainly used for reinforcement | Excellent for filtration and drainage systems |

| Cost | Typically more expensive due to durability | Typically lower cost, depending on application needs |

| Typical Applications | Road construction, embankments, erosion control, reinforcement | Drainage systems, landfills, landscaping, sediment control |

Material Composition

- Woven geotextile: Made using slit-film polypropylene or polyester yarns, woven together for strength and stability.

- Non-woven geotextile: Made using polyester or polypropylene properties that are bonded together through needle-punching, thermal bonding, or chemical processes.

When comparing polypropylene vs polyester, polypropylene is more resistant to moisture and chemicals, making it ideal for filtration and drainage applications. Conversely, polyester offers higher tensile strength and UV resistance, making it a better option for long-term soil stabilization and reinforcement.

Woven geotextiles are best for structural support due to their high tensile strength, whereas non-woven geotextiles excel in filtration and water permeability. If load distribution is the primary concern, woven geotextiles are the superior choice.

Non-woven geotextiles work better for projects that require moisture control, such as stormwater management, drainage, and sediment control.

Manufacturing Process

- Woven geotextile: Created by weaving synthetic fibers into a strong, grid-like structure.

- Non-woven geotextile: Manufactured using needle-punching, thermal bonding, or chemical processes, resulting in a more fabric-like, permeable material.

The weaving process makes woven geotextiles stiff and strong, ideal for reinforcing soil. Non-woven geotextiles, on the other hand, offer higher flexibility and better adaptability for filtration and drainage applications.

Strength & Durability

- Woven geotextile: High tensile strength, making it durable under heavy loads.

- Non-woven geotextile: Lower tensile strength but still durable for separation and filtration applications.

For long-term applications requiring reinforcement, woven geotextiles are the better choice because of their ability to withstand weight and pressure. Non-woven geotextiles are not as strong but are still suitable for temporary or non-load-bearing applications such as drainage.

Water Permeability

- Woven geotextile: Low permeability, which limits water flow.

- Non-woven geotextile: High permeability, allowing water to pass through easily.

Woven geotextiles block water movement, making them more suitable for stabilization projects where keeping the soil in place is essential. Non-woven geotextiles allow water to flow through them, making them better for drainage systems and erosion control.

Primary Use

- Woven geotextile: Generally used for soil stabilization and load distribution.

- Non-woven geotextile: Primarily used for drainage, filtration, and erosion control.

Woven geotextiles are the preferred choice for roads, embankments, and reinforcement applications. Non-woven geotextiles are better suited for moisture management projects, such as landfill liners and subsurface drainage.

Flexibility

- Woven geotextile: Stiff and less flexible compared to non-wovens.

- Non-woven geotextile: Soft, flexible, and easier to conform to uneven surfaces.

If a rigid structure is required, woven geotextiles provide better stability. However, non-woven geotextiles are more effective for projects that require a fabric that molds to irregular surfaces, such as around pipelines or landscaping.

UV Resistance

- Woven geotextile: Higher UV resistance due to tightly woven fibers.

- Non-woven geotextile: Lower UV resistance and may degrade faster under direct sunlight.

For exposed outdoor applications, woven geotextiles last longer because they better resist UV degradation. If non-woven geotextiles are used in an exposed area, they should be covered or replaced more frequently.

Resistance to Puncture

- Woven geotextile: More resistant to puncture due to its rigid structure.

- Non-woven geotextile: Less resistant to puncture but provides better adaptability.

Woven geotextiles perform best if a high-resistance barrier is needed, such as for roadways or heavy construction areas. Non-woven geotextiles are better suited for projects where adaptability is needed, such as wrapping around pipes or drainage layers.

Filtration & Drainage

- Woven geotextile: Limited filtration ability, mainly used for reinforcement.

- Non-woven geotextile: Excellent for filtration and drainage systems.

Non-woven geotextiles are the best option if water flow needs to be controlled or directed away. Woven geotextiles are not effective for drainage, as they restrict water movement.

Cost

- Woven geotextile: Typically more expensive due to durability.

- Non-woven geotextile: Typically lower cost, depending on application needs.

Woven geotextiles justify their higher cost with durability for long-term investments in roadwork and soil reinforcement. Non-woven geotextiles are a more cost-effective solution for short-term or non-load-bearing applications.

Typical Applications

- Woven geotextile: Road construction, embankments, erosion control, reinforcement.

- Non-woven geotextile: Drainage systems, landfills, landscaping, sediment control.

Woven geotextiles are used in high-strength applications where soil needs reinforcement. Non-woven geotextiles work best in moisture-related projects, including drainage and erosion control.

Not sure whether woven or non-woven geotextile fabric is right for your project? Contact us today for expert recommendations.

How to choose between woven & non-woven

Below, we break down real-world scenarios where each type excels, along with our recommended woven and non-woven products to get the job done right.

If You Need Soil Stabilization & Load Support – Use Woven Geotextiles

Woven geotextiles are the best choice for road construction, embankments, and heavy-load applications. Their high tensile strength prevents soil shifting and distributes loads effectively, making them ideal for foundation reinforcement and erosion control.

Recommended product:

- PP Woven Fabric – This fabric is specifically engineered for soil stabilization, reinforcement, and erosion control, providing long-lasting support in infrastructure projects.

Best applications for woven geotextiles:

- Road construction – Reinforces soil under asphalt and gravel roads.

- Driveways & parking lots – Prevents sinking and shifting.

- Erosion control – Protects slopes and embankments from soil displacement.

- Retaining walls – Strengthens backfill material for structural stability.

If You Need Drainage & Filtration – Use Non-Woven Geotextiles

Non-woven geotextiles are the best option for filtration, drainage, and sediment control. Their high permeability allows water to pass through while preventing soil erosion, making them perfect for stormwater management and underground drainage systems.

Comparing meltblown vs spunbond, spunbond non-woven geotextiles offer superior strength and durability, making them the preferred choice for landscaping and construction applications, while meltblown fabrics are typically used for filtration in masks and industrial applications.

Recommended product:

- Spunbond Fabric– A high-performance, non-woven fabric designed for drainage, filtration, and landscaping applications, ensuring effective moisture control.

Best applications for non-woven geotextiles:

- Drainage systems – Enhances water flow in French drains and underdrain systems.

- Filtration – Prevents fine soil particles from clogging pipes.

- Sediment control – Keeps silt and debris from entering stormwater systems.

- Landscaping & gardening – Acts as a weed barrier while allowing moisture retention.

If You Need a Multi-Purpose, Heavy-Duty Barrier – Use Woven Sandbags

What are sandbags used for? Our woven sandbags offer a durable and cost-effective solution for temporary flood barriers, erosion control, and industrial containment. These heavy-duty woven polypropylene sandbags can withstand high pressure and extreme weather conditions, making them ideal for construction sites, military applications, and emergency flood protection. Military sandbags are specifically designed for fortifications, tactical barriers, and blast protection, ensuring maximum durability in demanding environments.

Recommended product:

- Sandbag (Woven) – A reinforced woven fabric sand bags for sale designed for long-lasting durability and maximum protection in high-impact areas.

Best applications for woven sandbags:

- Flood control – Creates temporary barriers against rising water levels.

- Construction sites – Provides stability and weight where needed.

- Erosion prevention – Reduces soil loss in high-impact zones.

- Weighing down equipment – Keeps structures and tarps in place.

How to Make the Right Choice for Your Project

- For load-bearing and stabilization → Choose woven geotextiles.

- For drainage, filtration, and moisture control → Use non-woven geotextiles.

- For temporary barriers and erosion control → Opt for woven sandbags for maximum durability and strength.

By selecting the right fabric for your specific project, you can ensure better performance, cost-effectiveness, and long-term durability. If you need expert guidance, contact us today to find the best geotextile solution for your application.

Can’t decide between non-woven vs woven geotextile? Let our experts help you.

Choosing between woven and nonwoven geotextile fabrics can be challenging, but our high-quality products ensure you get the right solution for your project. At Palmetto Industries, we offer industry-tested durability, bulk discounts for contractors, and superior UV-resistant materials to provide long-lasting performance.

Our woven and nonwoven geotextiles are made using advanced manufacturing techniques, ensuring strength, flexibility, and resistance to puncture and wear.

Woven fabrics are generally used for separation and reinforcement and are made with slit-film polypropylene yarn for excellent tensile strength.

Nonwovens, such as our spun-bond polyester fabrics, provide outstanding permeability and filtration, making them ideal for drainage and insulation applications.

Unlike other textile products, our geotextiles are engineered with different materials and thermal bonding processes for enhanced longevity. Whether you need woven fabric for stability or nonwoven geotextile for water management, we have the right solution.

Our fabrics can also be used in applications where needle-punched nonwovens provide added durability and flexibility.

If you’re unsure which fabric is best for your project, contact us today to speak with our experts and find the perfect woven or nonwoven geotextile solution.

Key takeaways on woven vs non-woven fabric

Choosing between woven and non-woven geotextile fabric depends on your project’s needs.

- Woven geotextiles offer high strength and durability, making them ideal for soil stabilization, erosion control, and load-bearing applications.

- Non-woven geotextiles provide high permeability, making them best for drainage, filtration, and sediment control.

- Woven sand bags for sale, commonly produced by a sandbag manufacturer like ourselves, are a durable option for flood protection, construction, and erosion control.

For expert recommendations, reach out to our team today to find the best geotextile solution for your needs.