Poly Liners for Bulk Bags

What Is a Poly Liner?

A poly liner is a type of lining used in packaging. Also known as polyethylene liners or PE liners, these packaging liners are commonly made for use on the inside of a flexible intermediate bulk container, or FIBC for short, to keep the materials contained within it free from contamination.

Polyethylene, the material used to make liners, is a thermoplastic polymer with a variable crystalline structure and a wide range of uses depending on the particular type. It is one of the most widely produced plastics in the world, with tens of millions of tons produced worldwide each year.

What Is a Poly Liner Used For?

A polyethylene liner is the perfect solution to protect the inner contents of a bulk bag when transporting and storing goods. They are used in a variety of different industries and applications where bulk bags are being used. These liners can be added to already purchased bulk bags or come manufactured with the liner installed on the inside of the bag.

Some examples of items that are transported in bulk bags with poly liners:

- Seeds

- Flour

- Chemicals

- Grains

- Powders

Bulk Bags

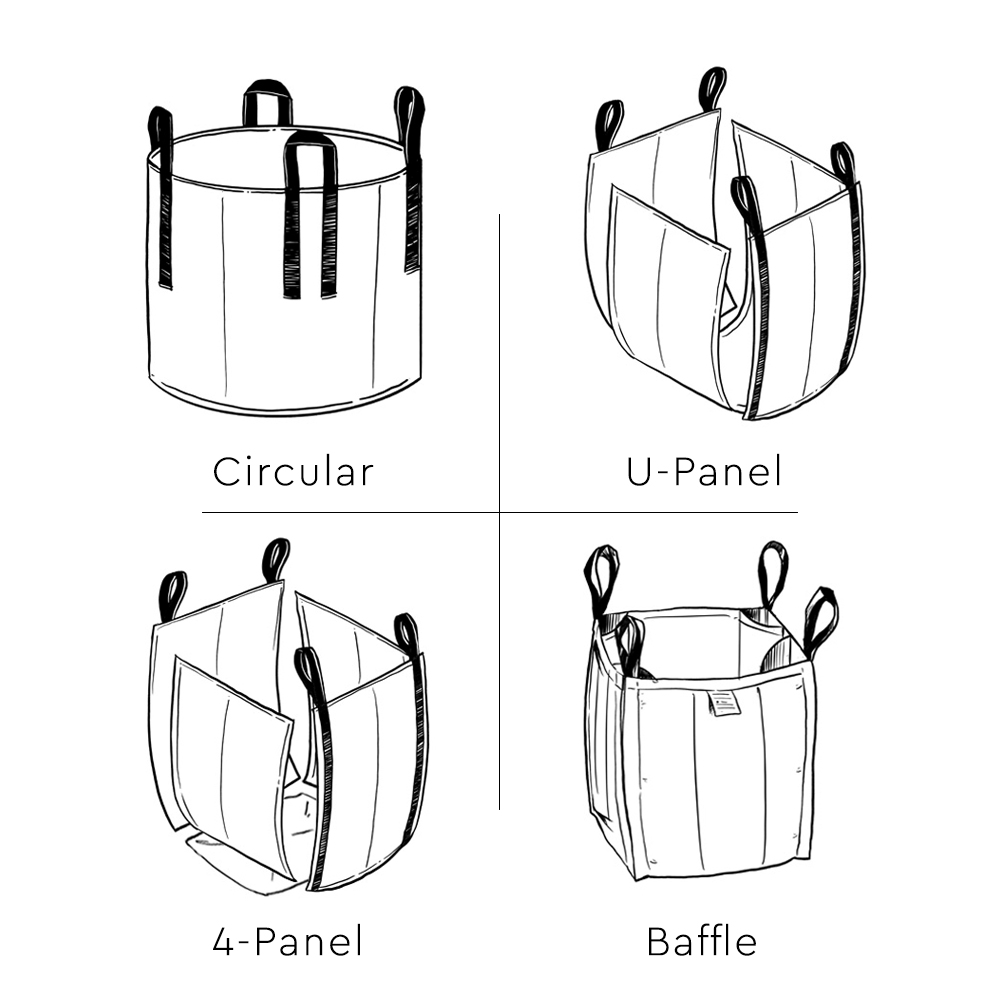

FIBC bulk bags come in several different construction types. These varying types change the features and attributes of the bag so it’s important to consider the differences when looking into purchasing.

There are 4 main construction types:

- Circular bags: One piece of fabric forms all 4 sides of the bag with a single piece sewn on to the bottom and top.

- U-panel bags: One piece of fabric forms 3 sides, two opposite sides and bottom. Two additional sides are sewn into the larger piece to form the bag.

- Four-panel bags: The industry standard, 4 separate panels are sewn together along the seams with a single piece being sewn along the bottom.

- Baffle bags: Baffle bags have additional pieces of fabric sewn across each corner to allow the bag to retain its square shape when filled.

What Industries Use Poly Liners?

Food

The food industry often handles many materials that require a complete lack of contamination. Many food items contain powders or other sensitive materials not meant to be exposed to the elements. This is why having a poly liner in your bulk bag is crucial. Any type of contamination to the product contained in the bag could cause numerous safety issues.

Pharmaceutical

Much like the food industry, pharmaceutical items such as medicine must be kept free from contamination. Many medicines are complex formulas made from a precise blend of chemicals. Exposure to even the slightest bit of outside contaminants can be detrimental.

Bulk bags and other poly liner packaging is used to transport these goods and keep them from being ruined by weather and other sources of outside exposure.

Powders

One thing to worry about when transporting very fine items is leakage. While different materials have different levels of risk when considering transportation, fine powders are definitely at risk of leaking through a seam. Many bags and other containers are not built to be air-tight and thus are at risk for a powder leak. Leaking can be detrimental when moving a large quantity of a substance across a considerable distance.

This is where FIBCs with liners come into play. These poly-lined bags serve as air-tight conduits for a cargo composed of fine powder. The aim is to prevent product loss over long distances and potentially hazardous situations.

Chemicals

A poly lining will keep outside contaminants such as dust, liquids, and moisture from reaching the chemicals inside the bag, which can be crucial when the insides of a package include chemicals that need to stay pure.

Polyethylene Liners: Key Takeaways

Polyethylene liners are an important aspect of safely transporting sensitive materials. These liners have a history of keeping products safe from moisture and preventing build-up that can ruin many types of goods in these containers.

We’re experts when it comes to all things bulk bags. Choosing the correct type of poly liner depends on your product’s needs. Assessing your product’s size, bag size, and needed ventilation, if any, are all important considerations. Give us a call or shoot us a message today so we can discuss how to safely and securely transport your goods.