Types Of FIBC Bags: A, B, C & D FIBC Types Defined.

For starters, FIBC stands for Flexible Intermediate Bulk Container, or bulk bag. But knowing the different types of FIBC bags ensures you have the perfect solution for your business or need. We’re here to simplify it for you. Read below the different options and find out which is best for your job, or pick up the phone and give us a call.

What are the different types of FIBC bags?

There are four main types of FIBC bags. A, B, C, and D. When FIBCs are filled and discharged, it is possible for the movement of the contents to have a buildup of static electricity. Stopping this electrical charge from increasing is crucial if you are dealing with flammable and combustible materials. Other materials may not have issues with flamibility.

01. Type A FIBC Bags (no electrostatic protection)

Type A FIBCs provide no static protection. Made of woven polypropylene (woven pp), static electricity is generated as materials rub against the inside surface of the bag as they are filled and emptied. Since there is no static protection provided by Type A bags, it is essential that they are not used to store or transport combustible materials, or used in flammable or combustible environments.

Primary Uses for Type A FIBCs:

- Non-hazardous materials.

- Locations with non-hazardous conditions.

Do NOT use for:

- When transporting flammable or hazerdous materials.

- When flammable materials or gases are present in your location.

- When a flammable atmosphere with minimum ignition energy less than 1,000mJ is present.

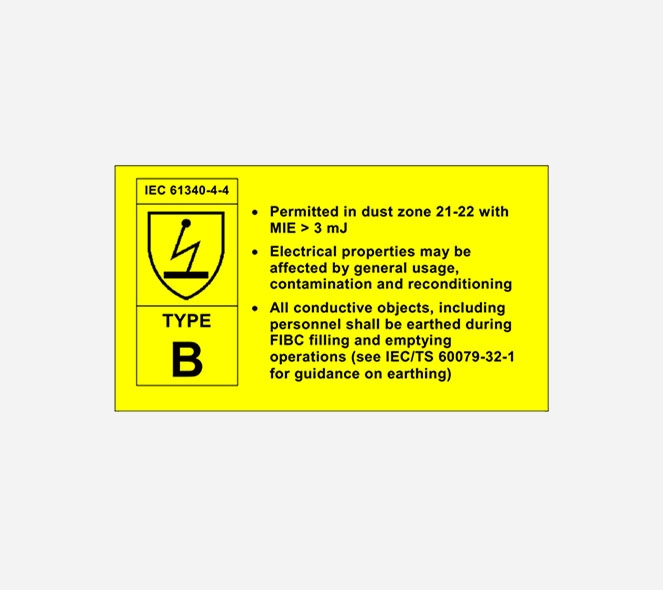

02. Type B FIBC Bags (Surface breakdown voltage of <6kV)

Like Type A bulk bags, Type B bulk bags do not have any mechanism for dissipating static electricity. The difference is that Type B bulk bags are made from materials that have a low breakdown voltage to prevent the occurrence of highly energetic, and dangerous propagating brush discharges (PBD). Although Type B FIBCs can prevent PBD, they cannot be considered antistatic FIBC because they do not dissipate electrostatic charge. Normal brush discharges can still occur, which can ignite flammable solvent vapors.

Primary Uses of Type B FIBCs:

- Transporting dry, flammable powders

- Where no flammable solvents or gases are present.

- Environments with dust with ignition energies less than 3mJ.

Do NOT use for:

- When transporting flammable or hazerdous materials.

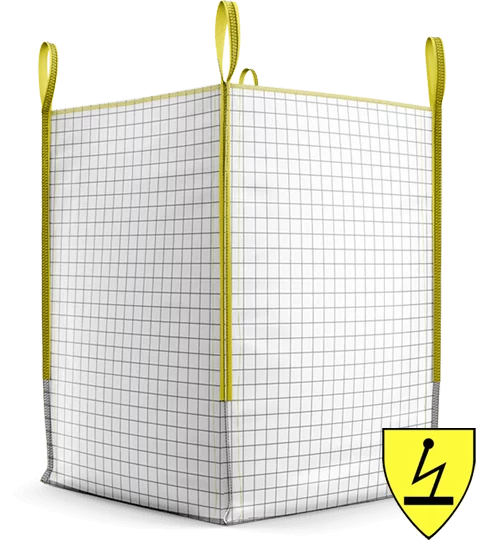

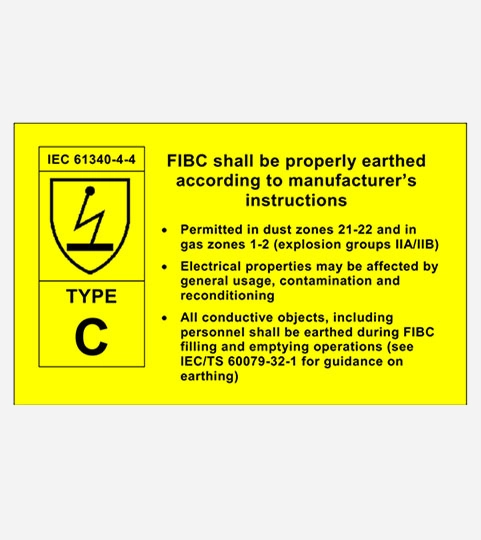

03. Type C FIBC Bags (Electrically conductive or groundable)

Are also known as conductive or groundable FIBC. Originally they were made from entirely conductive materials. Groundable Type C FIBCs are more commonly made from non-conductive polypropylene interwoven with conducting yarns, normally in a grid pattern. The interconnection of conductive yarns and the connection to ground or earth are critical to the safe use of Type C FIBC. As with any manual operation, ensuring interconnection and grounding of Type C FIBC is subject to human error.

Primary Uses for Type C conductive FIBCs:

- Transporting flammable powders.

- When flammable vapors, gases, or combustible dusts are present.

Do NOT use for:

- When ground connection is not present or has become damaged.

- Resistance from any location FIBC to ground-able point.

- When a flammable atmosphere with minimum ignition energy less than 1,000mJ is present.

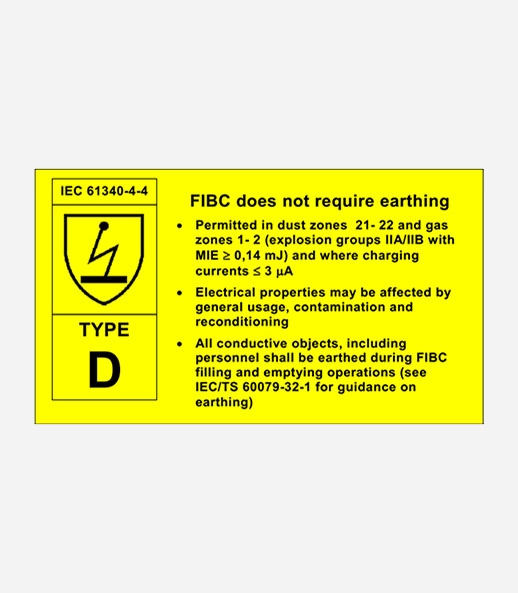

04. Type D FIBC Bags (Crohmiq static dissipative or antistatic)

Anti static bulk bags are made from static protective fabric designed to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges, without the need for a connection from the bulk bag to ground or earth. Using CROHMIQ fabric to construct anti-static bulk bags eliminates the inherent risk of grounding failure that is always present whenever conductive Type C FIBCs (grounded FIBCs) are used.

Primary Uses for Type D antistatic FIBCs:

- Transporting flammable powders

- When flammable vapors, gases, or combustible dusts are present.

Do NOT use blue Crohmiq bulk bags for:

- When surface of FIBC is contaminated or coated with conductive material such as grease or other flammable and/or combustible materials.

COATED VS. UNCOATED.

FIBC bags are used across a varying array of industries and for many different applications. The type of product you will be storing and shipping will determine whether or not you need a coated or an uncoated bag.

COATED:

Coated FIBCs are produced with a laminated layer of polypropylene film to provide a moisture barrier, dust prevention, and weave stability.

APPLICATIONS:

Transporting and storing dry and free flowing products that come in granule, powder, or crystal form such as:

- Flour, detergents, or salt.

- Fine minerals like sand and sugar.

- Various chemicals, glass, steel, and milled corn.

UNCOATED:

Uncoated FIBCs are made without a layer of lamination that coated bags have. Their weave construction allows air to pass through. Various weave designs are available for highly specialized breathable and ventilation applications.

APPLICATIONS:

Uncoated bags are typically utilized for:

- Products that require breathability

- Food products, such as potatoes, onions, peanuts, tree nuts, coffee beans, etc.

- Minerals such as rocks, gravel, sand, etc.

Different kinds of FIBC bag styles

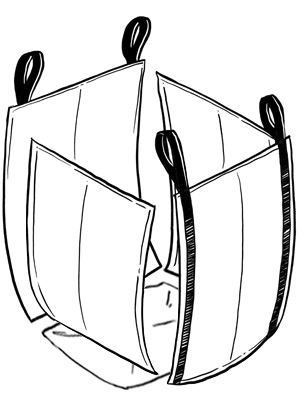

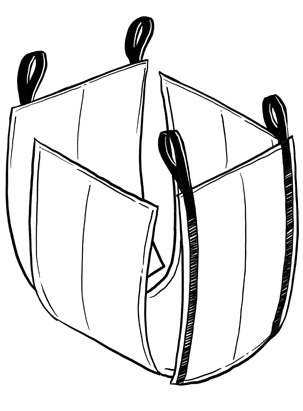

One piece of fabric forms 3 sides, two opposite sides and bottom. Two additional sides are sewn into the larger piece to form the bag.

One piece of fabric forms all 4 sides of the bag with a single piece sewn on to the bottom and top.

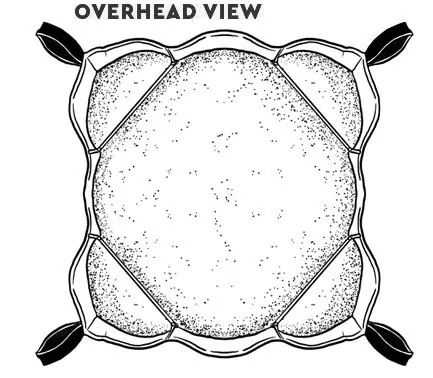

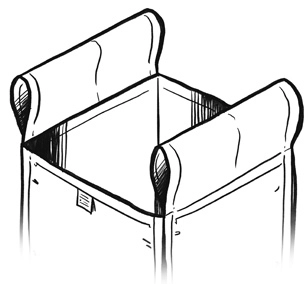

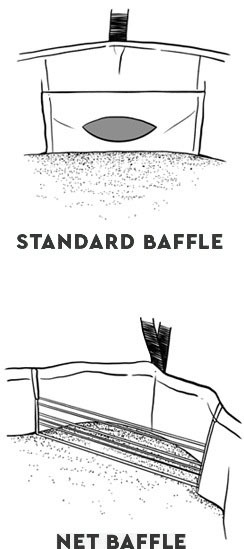

Baffle bags have additional pieces of fabric sewn across each corner to allow the bag to retain its square shape when filled.

Baffle bags can hold up to 30% more volume per bag when utilizing the same footprint, allowing for enhanced stability when stacking and enhanced space optimization when storing and transporting.

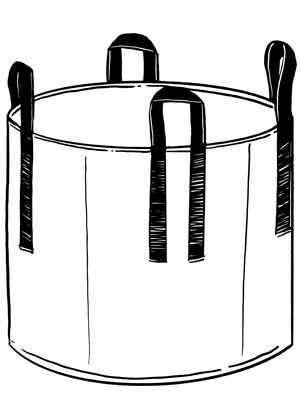

FIBC BAGS: LOOP CONSTRUCTION

Each loop is sewn into the seams in the corners of the bag.

Each loop is sewn into one side of the FIBC.

Two straps put through each set of lift loops to allow easy moving by forklift.

A single strap is put through all four loops to allow lifting from multiple sides.

Made of the same woven polypropylene as the bag, they are made for use with forklifts.

TYPES OF FIBC BAGS' TOP CONSTRUCTION

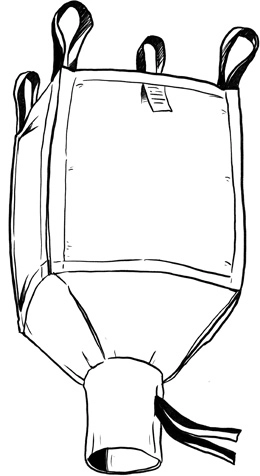

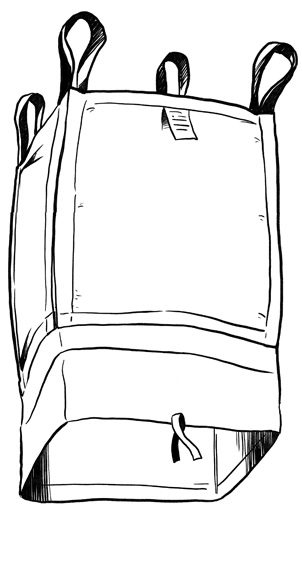

Standard bulk bag construction with an open top, just as the name implies.

Lightweight top panel to provide better filling options and also a closure.

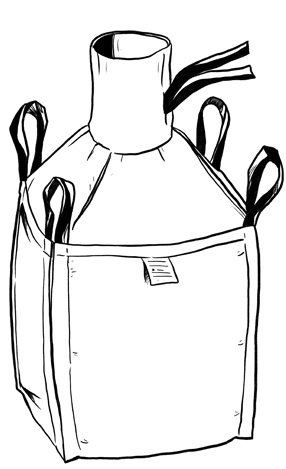

Cylindrical spout sewn on the top panel of the bag. Works best for more specific applications.

Cylindrical spout top with additional flap for added coverage over the sealed spout.

Cylindrical spout top with a high filling cone for specific applications.

BOTTOM CONSTRUCTION OPTIONS FOR FIBC BAGS

Standard bottom construction with no means of discharge.

Standard discharge spout for easy removal of bags contents.

Standard discharge spout for easy removal of bags contents.

Standard discharge spout for easy removal of bags contents with an additional flap for extra coverage.

Lightweight bottom panel that provides quick and easy discharge of bags contents.

Which type of flexible intermediate bulk container bags are right for me?

If you're wondering which type of flexible intermediate bulk container bags are right for your business, look no further! Our experts are here to help you find the best FIBC solution tailored to your specific needs and requirements.

Contact us today and let us guide you through the selection process. With our vast range of options and a robust FIBC bags manufacturing process, we're confident that we can find the perfect solution for your business.

Not sure which of the bulk bag discharge types is right for you? Contact us now.

If you’ve got questions or want to talk bulk bags, we want to listen! There are many bulk bags and bulk bag discharge types to choose from. Give us a call or fill out the form and we’ll be in touch!

- Our Location

6050 Horizon West Parkway

Grovetown, GA 30813 - Phone Number

+1 706-737-7999 - Email

info@palmetto-industries.com

Get a quote today!

Fill out the contact form below and one of our product

experts get back with you as soon as possible!