Bulk Bag Unloading Guide | FIBC Handling Equipment Tips

Bulk Bag unloading can be a challenging and time-consuming process that poses significant obstacles for industries relying on efficient bulk bag handling.

Without appropriate machinery designed to handle super sacks, manual unloading becomes labor-intensive, prone to errors, and potentially hazardous.

By employing proper techniques and investing in bulk bag handling equipment, businesses can overcome the challenges associated with super sack unloading, enhance operational efficiency, and minimize potential risks. Images in this article appear courtesy of our friends at Palamatic Process, a leader in the bulk material and powder handling industry.

Let’s start off with some general guidance and tips…

Bulk Bag Handling General Tips & Advice

Image credit: Palamatic Process

- Safety first: Prioritize safety at all times when handling super sacks by ensuring personnel are adequately trained and that they’re equipped with appropriate PPE.

- Pre-handling inspection: Before handling a super sack, inspect it for any damage, tears, or defects. Check for proper labeling and ensure that the bag is suitable for the material.

- Load capacity: Be aware of the weight capacity of the super sack and adhere to it strictly. Overloading can lead to bag failure and accidents.

- Secure attachment: Ensure that the super sack is securely attached to the handling equipment, such as lifters or hooks, before lifting or moving it. Use proper lifting techniques and follow the manufacturer’s guidelines to prevent bag slippage or instability during handling.

- Avoid bag damage: Avoid dragging or sliding the bag on rough surfaces, sharp edges, or abrasive materials that could cause tears or punctures.

- Proper storage: When storing super sacks, keep them in a clean and dry area, away from direct sunlight, extreme temperatures, or exposure to moisture. Protect the bags from pests or rodents to maintain their integrity until further use.

- Training and communication: Promote effective communication and collaboration among employees involved in super sack handling. Encourage them to report any issues or concerns promptly. Regular training sessions and feedback sessions can help improve handling techniques and safety awareness.

- Environmental considerations: Dispose of used or damaged super sacks responsibly, adhering to local regulations. Consider recycling or reusing the bags where possible to minimize waste.

- Regular maintenance: Maintain the handling equipment in good working condition through regular inspections and preventive maintenance. Address any issues promptly to ensure safe and efficient handling operations.

In addition to these general tips, though, consider them in conjunction with the specific guidance below on unloading and loading…

Bulk Bag Unloading & Loading Tips

When it comes to unloading and loading super sacks, there are a few tips to keep in mind to ensure efficiency and safety:

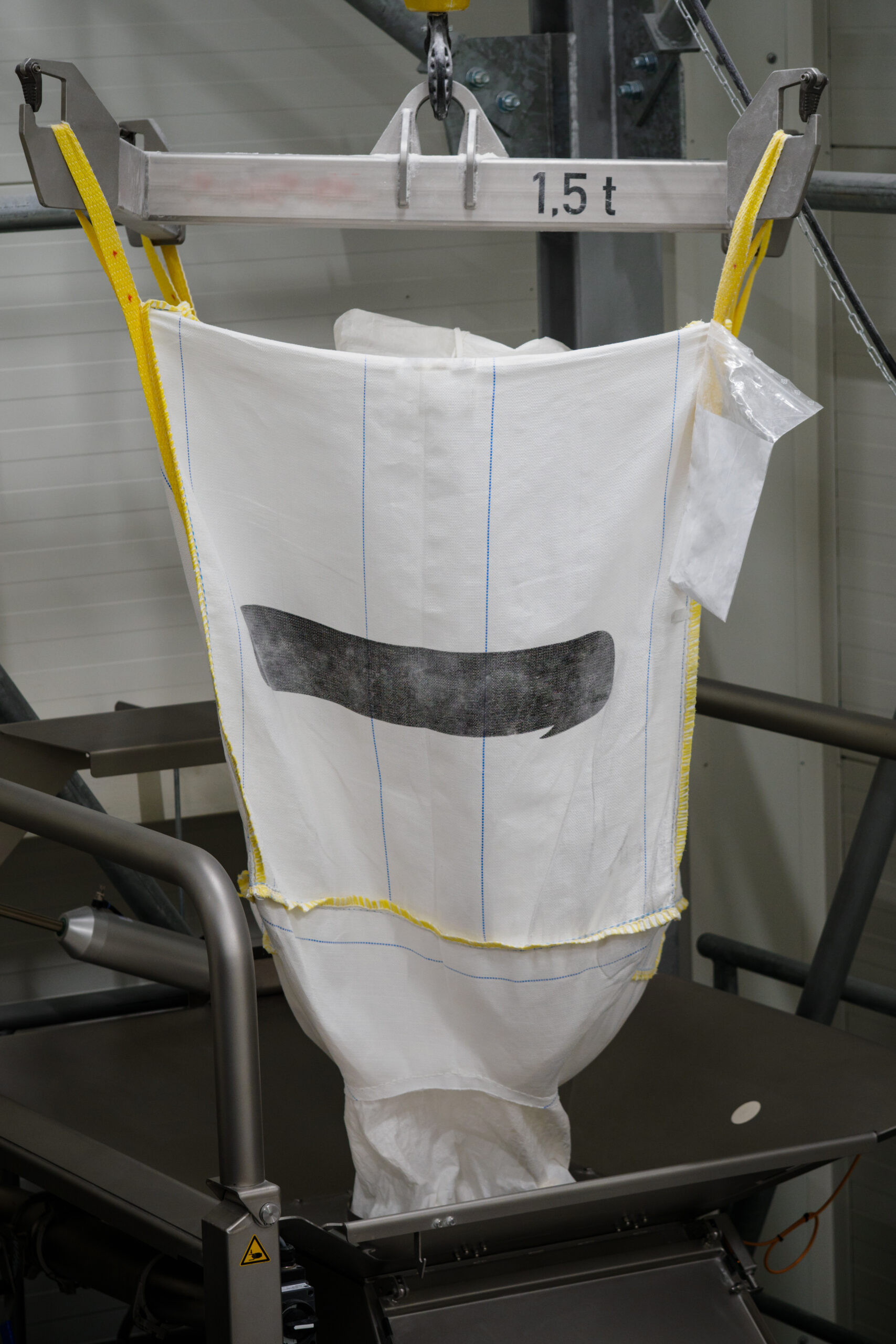

Image credit: Palamatic Process

- Bag inspection: First and foremost, always inspect the super sacks for any damages or defects before unloading or loading them. This will help prevent any spills or accidents.

- Appropriate equipment: Choose appropriate equipment for unloading and loading, depending on the weight and type of material in the super sacks. For example, using automated machinery, such as forklifts or cranes, can save time and reduce the risk of injuries (more on this below!).

- Get organized: When unloading or loading, having a clear and organized workspace to prevent any obstacles or tripping hazards. This includes ensuring any routes that the equipment needs to move through are clear.

- Apply the correct techniques: Even though you’re likely to use handling & loading equipment, some form of manual labor will still be needed. So, ensure you follow proper manual handling guidelines to avoid strain or injuries.

- Communication: Lastly, communicate with the team and establish clear signals and instructions to ensure everyone is on the same page during the unloading and loading process.

Bulk Bag Handling Equipment Options

Handling bulk bags can often be a challenging task, especially if you don’t have the right equipment.

Whether you’re dealing with materials like grains, chemicals, or construction debris, having the proper bulk bag handling equipment can greatly improve efficiency and safety in your operations.

Let’s take a look at some of the best bulk bag handling equipment options right now:

Bulk Bag Unloaders

Designed with precision engineering, this super sack unloading system is specifically designed to handle multiple super sacks and large quantities of bulk materials with ease, ensuring a seamless and quick process.

Featuring a robust and durable construction of stainless steel or carbon steel, bulk bag unloaders are also built to withstand heavy-duty applications and unloading materials with high densities, such as powders, grains, or granules.

In addition, bulk bag unloaders are equipped with various features to enhance their durability. For example, reinforced frames, heavy-duty hinges, or stabilizing supports to withstand the stress of continuous use over time.

Bulk bag unloaders are also built to withstand extreme temperatures or corrosive environments, ensuring their longevity and performance even in harsh conditions. This makes them suitable for a wide range of industries, including agriculture, food processing, mining, or construction.

Bulk Bag Lifting Device

With its robust construction and intelligent design, it ensures the effortless lifting of heavy loads. This is mainly due to its sturdy frame providing the stability, while the high-quality construction materials guarantee durability and longevity.

It also prioritizes safety during unloading with advanced safety features, including secure attachment points for the bags, reducing the risk of accidents or spills. This ensures the protection of both personnel and materials, creating a secure work environment.

One of the other notable features is its adaptability. It can accommodate various super sack sizes, making it suitable for a wide range of applications and a customized fit, ensuring efficient unloading regardless of the dimensions or materials being handled.

This reliable bulk bag lifter reduces unloading downtime, saving valuable time and resources. With its ability to handle heavy loads effortlessly, it streamlines workflow and increases productivity.

Bulk Bag Discharger/Dispenser

Image credit: Palamatic Process

A bulk bag discharger/dispenser is a specialized equipment designed to facilitate the efficient and controlled unloading of bulk bags, whether it’s powders, granules, or other materials, into downstream processes or storage containers.

This equipment typically consists of a sturdy frame with a platform or cradle to support the bulk bag during unloading and various features to ensure a smooth and controlled discharge process. These features may include adjustable bag retention devices, spout interfaces, and material flow control mechanisms.

It also offers versatility in accommodating different sizes and types of bulk bags, designed to securely hold and stabilize the bag during the unloading process, preventing potential spills, leaks, or accidents.

The controlled discharge mechanism allows operators to regulate the flow rate of the material, ensuring accuracy and preventing overfilling or product loss. In addition, some models feature integrated conveyors or hoppers to further streamline material transfer.

Bulk Bag Hopper

Typically, a super sack hopper consists of a sturdy frame or structure with a large receiving chamber, usually made from steel, stainless steel, aluminum, or a composite material. This makes them ideal for handling powders, granules, or bulk solids.

No matter the material, they’ll all securely hold the super sack while providing a convenient opening for the bag’s discharge spout, preventing the bag from shifting or tipping during unloading.

Moreover, various features facilitate efficient material flow, promote consistent discharge and prevent material bridging or clogging:

- Integrated agitators

- Flow promotion devices

- Vibrators

Bulk Bag Stand

A Bulk Bag stand, also known as a super sack stand, is a support structure designed to securely hold and elevate bulk bags during storage or handling. It provides a stable platform for the bags, ensuring their structural integrity and preventing damage or collapse.

By lifting the bag, it helps prevent potential damage caused by moisture, pests, or contact with rough surfaces. This elevation also facilitates easy access to the bag during loading, unloading, or sampling procedures.

Typically constructed from sturdy materials, such as steel or heavy-duty plastics, a super sack stand consists of a frame with multiple legs or supports. In particular, the stand is designed to accommodate the size and weight of the super sack, providing ample space for the bag to rest without compromising its stability.

A well-designed super sack stand also incorporates features that ensure safe and efficient handling, such as:

- Sturdy base for stability

- Protective coatings to prevent corrosion

- Additional accessories (bag liners or spout adapters) for added convenience.

In terms of industries, super sack stands are particularly beneficial for businesses that handle bulk materials regularly, such as agriculture, construction, and manufacturing.

In the market for bulk bag handling solutions? Consider Palmetto Industries’ bulk bags

Palmetto Industries is a leading manufacturer of bulk bags that are designed to provide efficient and reliable solutions for handling and transporting large quantities of materials.

Whether you need bulk bags for storing or transporting chemicals, agricultural products, construction materials, or any other bulk materials, we have a solution for you.

With our extensive experience and expertise in the industry, you can trust that our bulk bags will meet your specific needs and exceed your expectations.

Get in touch with our team today so we can discuss your needs further.

Key Takeaways On Bulk Bag Handling Equipment

With the ability to lift and transport heavy super sacks with ease, super sack handling equipment minimizes the manual effort required and allows workers to handle more sacks in a shorter amount of time.

Additionally, it ensures worker safety by reducing the risk of injuries that may occur from lifting heavy loads and is designed to accommodate different types of sacks, designed to fit various sizes and weights.

This adaptability makes it a valuable investment for businesses dealing with a wide range of sack sizes.