7 Different Bulk Bag Discharge Types: All You Need to Know

Flexible Intermediate Bulk Containers (FIBCs) are bulk bags made from flexible, woven materials and can typically hold between 500 kg and 2,000 kg of flowable product. There are several different FIBC construction methods and bulk bag discharge types to consider, depending on your application.

How Many Bulk Bag Discharge Types Are There?

Bulk bags are used in industries like food production, chemical handling, building, construction, and mining operations. In this article, we cover the seven main types of bulk bag discharge types available today.

Keep in mind that there are multiple bulk bag unloader methods. Some companies use a forklift, pneumatic or screw conveyor, stationary frame, specialized unloading station, or a hoist to empty their FIBCs. Choosing the best discharge methods and the types of FIBC bags required will depend on the material handling techniques used in your organization.

What Are the Different Bulk Bag Discharge Types?

As bulk bag users are looking for improved ways to discharge products every day, there are custom bags available that can handle almost any kind of situation.

You can combine different bulk bag discharge types with a variety of protection methods as per your requirements. A dust-free FIBC may use a conical discharge bag spout or a plain bottom, depending on your needs.

The seven main bulk bag discharge types are:

- Plain bottom

- Discharge spout

- Conical discharge spout

- Discharge spout with flap

- Duffle bottom

- Diaper bottom

- Iris closure

Here is what you need to know about the most common FIBC construction types and discharge methods:

Plain Bottom (No Spout)

A plain bottom FIBC without a spout (also called a plain base or flat-bottom bulk bag) is an economical option but can only be used once. To discharge the product, you need to cut open the bottom.

These FIBCs are usually found in operations where discharge isn’t part of the process or where you need fast discharge without needing to reuse the bag.

Bulk Bag Discharge Spout Closure

FIBCs that have a discharge spout are ideal for when you need to reuse the bulk bag. The spout is part of the bag’s construction and doesn’t harm the bag during discharge.

The size of the spout ranges between 14 inches in diameter and 18 inches in length, but you can easily adjust the dimensions to suit your needs. Bulk bags with a discharge spout are the most popular in the industry.

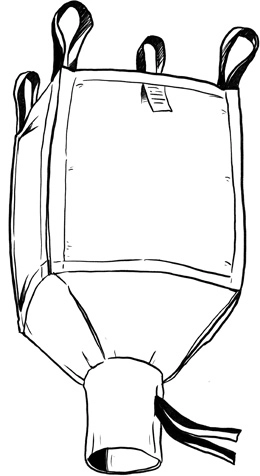

Conical Discharge Spout

A conical discharge spout helps when you want to ensure that you empty the entire bag of its product. One common issue with standard FIBCs is that material accumulates in the corners of the bag.

With standard bag discharge types, users need to shake the FIBC to remove all the material. A conical discharge spout lets material flow easily from the bottom of the bulk bag without any leftover product remaining stuck in the corners.

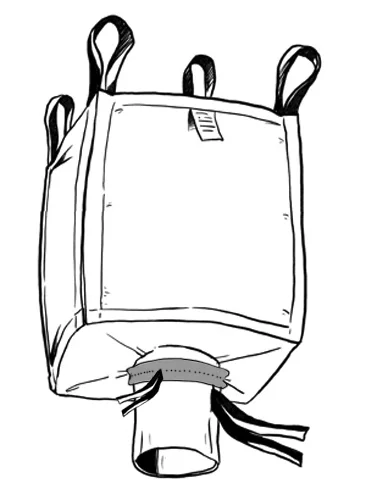

Discharge Spout with Flap

To protect the spout from moisture, you can opt for a discharge spout with a flap. The flap, made from tough fabric, attaches to the base of the bag before securing it with a band to prevent dust collection.

Flaps fit the same dimensions as the bulk bag and act as access doors for the spout. When contamination is a concern, protecting the discharge spout with a flap is the best option.

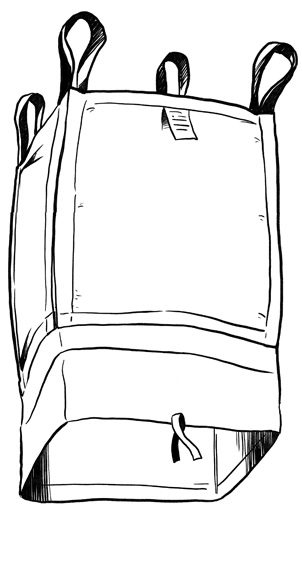

Duffle Bottom Bulk Bag Discharge Type

A duffle bottom allows you to discharge all the contents of the bag quickly and easily. Mainly used for bulk material, the entire bottom of the bag opens to release product that doesn’t flow easily or clumps together over time.

You fasten the bottom of the bag using a polypropylene tie that may include a perimeter closure to secure the product during transport and storage. Some duffle bottom bulk bags also use a flap to protect the bag until discharge.

Diaper Bottom FIBC Discharge

Sometimes called a full drop bottom, diaper bottom bulk bags use a flat piece of fabric connected to one side of the FIBC. You can tie the flap to the other side of the bag, allowing you to release the entire bottom to discharge the material.

Diaper bottom bulk bags are ideal when you want a simple discharge solution that doesn’t require you to slice the bag open, like with plain bottom FIBCs.

Iris Closure and Discharge FIBC

When you don’t need a fixed connection, an iris bottom provides you with a way to control the flow of material using an iris valve. The discharge spout pulls through the valve, which you then secure around the spout.

Once you gradually open the valve, the material starts discharging and you can prevent any uncontrolled blasts, limiting dust from spreading through your plant area during product flow.

Our Conclusion about the Kinds of Bulk Bag Discharge Closures

For any kind of bulk material handling where the product is flowable, you can find a discharge type that suits your needs.

Even when the above types do not fit your exact requirements, custom discharge designs are available that will ensure you can transport, store, and discharge your product safely.

FAQs on Types of Bulk Bag Discharge

What Are Bulk Bags and Spouts Made From?

Most bulk bags are made from polypropylene materials that provide high strength and come in reusable designs.

How Do I Decide Which FIBC Discharge Type to Use?

The type of design you choose will depend mainly on the materials you manage, but the cost is another factor. If you only transport materials one time through, then single-use FIBCs are fine. When you need to reuse a bag, you’ll need to discuss your requirements with the manufacturer.

Do I Need to Have a Flap on My Bulk Bag Discharge Spout?

Flaps are only required when you need to protect the bottom of the bag in transport or prevent contamination of your product during discharge. You should also consider how well your choice of design works with product massagers, load cells, pneumatically operated fillers, or other process equipment.

Where Can I Find More Information about Bulk Bag Discharge Types?

To learn more about bulk bag discharge types, you can contact a manufacturer like Palmetto Industries who will guide you through the entire selection process.

For companies looking to move away from stainless steel silos during batching, storage, and bulk material handling processes, FIBCs are the ideal alternative to save you time and money.