FIBC Bulk Bags are made to store and transport a wide array of different products and materials. When it comes to the storage and transportation of certain hazardous materials, standard bulk bags don’t always meet the safety requirements that are essential for the safe handling of these types of products. That’s where UN Certified bulk bags come in. UN Certified Bulk Bags are designed specifically to meet the requirements set forth by the United Nations for transporting and storing hazardous materials. In order to be classified as such, the bags must undergo rigorous testing methods. Our sales experts are highly knowledgable when it comes to these requirements. We can give you an in-depth analysis of your current specs and determine which type of UN approved bulk bags are the best solution for you.

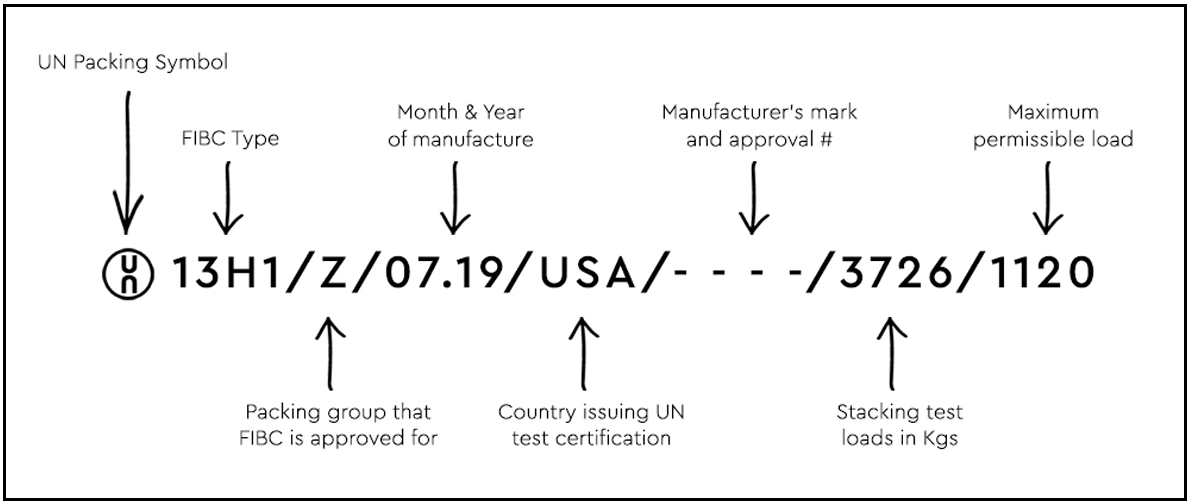

UN FIBC bags labeling & identification

UN FIBC bags have a unique labeling system designed to allow the user to track the origin, materials, manufacturer, coating, and other important factors of the individual bag. See below for an explanation of the labeling system.

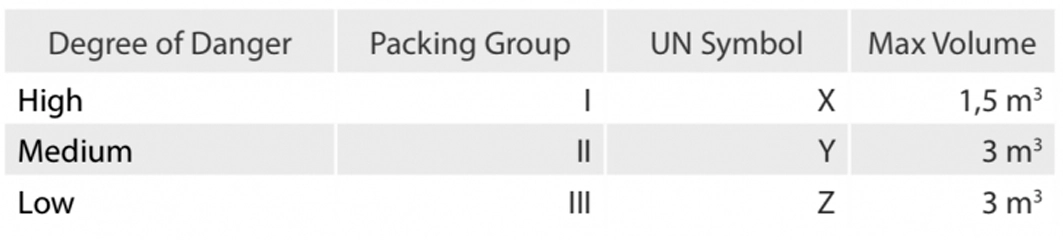

Categories of UN Approved Bags:

Dangerous products are classified by the United Nations by a unique UN product number, which must be attached to your UN approved bags. These product numbers and corresponding packaging group classifications, below, can also be found in the “orange book.”

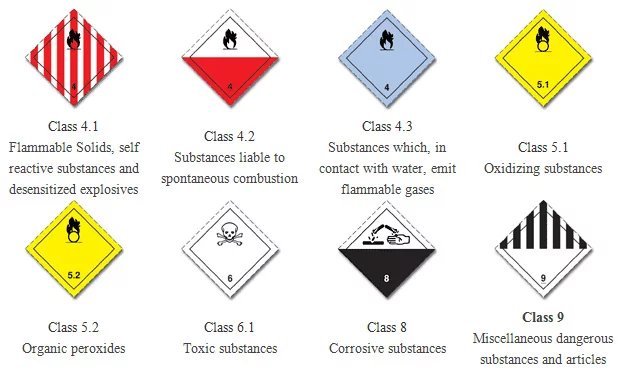

Classes of UN rated bags:

Why choose Palmetto Industries to supply your UN certified bags?

All of our UN Certified bags for hazardous materials are rigorously tested, examined, and designed specifically for the handling of hazardous materials for Packaging Groups II and III Materials in Chapter 9 of the United Nations “Orange Book”. To be able to determine your requirement all we need is the UN classification of the product to be packed and transported. Based on that information we will design your UN Bags to meet your exact requirements.

We rigorously test our UN rated FIBC bags

To ensure each of the bags that are labeled as a UN rated FIBC are able to safely transport and store all types of hazardous waste and materials, they must each go through rigorous testing procedures. See below for a brief overview of what those tests involve.

1) Vibration Testing

The bags are put through a rigorous vibration test for 60 minutes and must not rupture and have no leakage.

2) Top Lift Testing

The bags are lifted from the top and must maintain it’s integrity with a 6:1 SWL (Safe Working Load) for 5 minutes. There must be no loss of contents or permanent deformation.

3) Stack Testing

A top load is placed on a filled bag for 24 hours. The top load weighs 1.8x the combined maximum permissible gross mass of the bags that may be stacked on top. There must be no loss of contents or deterioration of the bag.

4) Drop Testing

The bags are dropped from 3 specific heights based on the packaging group. There must be no loss of contents.

5) Topple Testing

The bags are toppled from a specific height based on the packaging group. There must be no loss of contents.

6) Righting Testing

The bags are lifted to an upright postion from it’s side. There must no damage to the bag.

7) Tear Testing

The bags are punctured with a knife at a 45° angle. Part 1 of the test is a uniform top load with the maximum permissible safe working load. The bag must remain in tact for atleast 5 minutes. Part two of the test requires the bag to maintain it’s integrity with a 45° cut when being suspended for 5 minutes. The cut must not propogate to more than 25% of it’s original length.

Our UN rated bulk bags follow The Orange Book Guidelines

The Orange Book, as it is better known, is the set of recommendations provided by the UN for FIBC Bulk Bags carrying dangerous goods to prevent injury to people, harm to the environment, and material damages.

The book divides UN rated bulk bags into six categories, namely flexible, rigid plastics, composite, fiberboard, wooden, and metal. There are 4 types of bulk bags named which cover the majority of FIBCs used:

- 13H1 - Woven PP fabric w/o coating or inner liner

- 13H2 - Woven PP fabric, coated

- 13H3 - Woven PP fabric w/ inner liner, w/o coating

- 13H4 - Woven PP fabric, coated and w/ inner liner

Palmetto Industries has been a provider of UN FIBC bags for over 25 years and our experts are here to answer any questions you might have on our UN certified bags or other Palmetto Industries International products, so please call us at 706-737-7999 or email our sales team at sales@palmetto-industries.com.

Shop UN Certified Bulk Bags