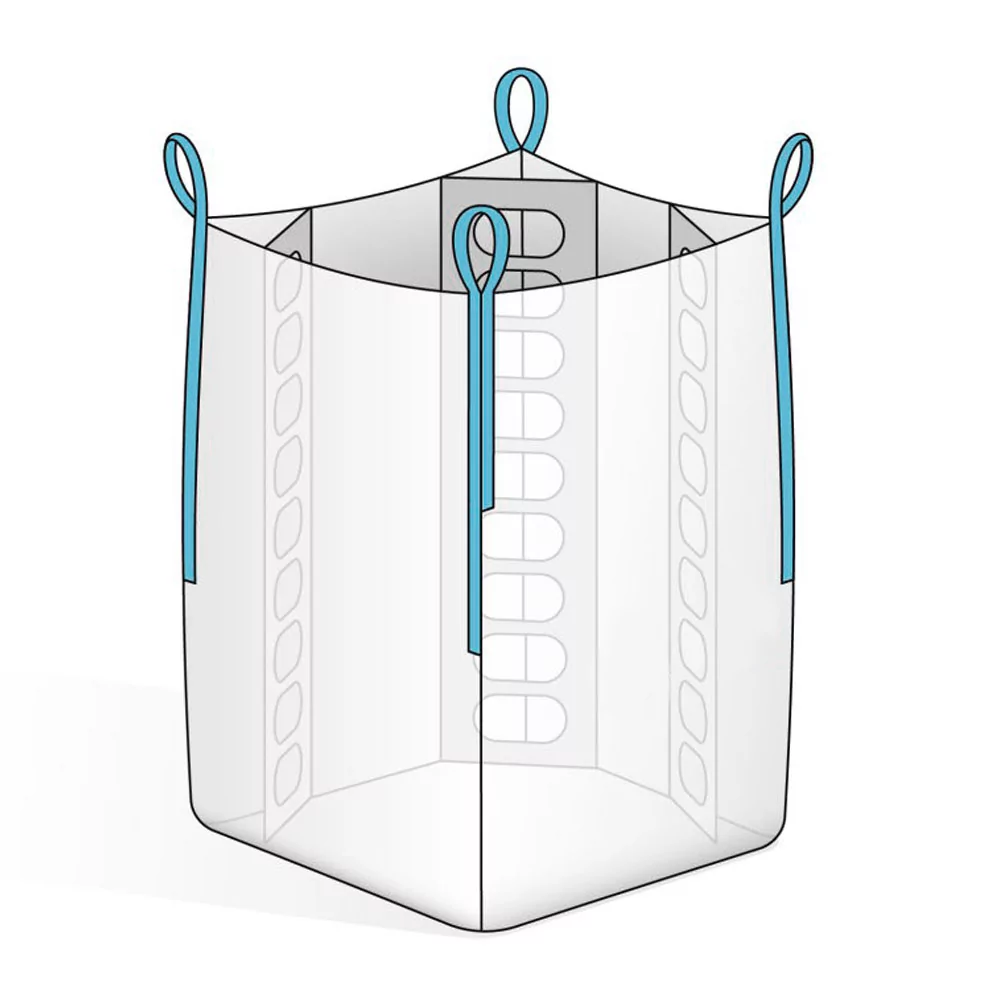

Our baffle bulk bags are unique in that they have a piece of fabric sewn on each corner to maintain that square shape akin to bulk bags that you’re likely familiar with. This baffle bag structure allows shape rigidity and structure when filling, storing and transporting goods and waste.

Benefits Of Our Baffle Bulk Bags

Our focus as bulk bag suppliers is to ensure we maintain the highest-quality product standards.

Even though the below are widespread features across all our offerings, such as with our food-grade bulk bags and UN-certified bulk bags, our baffle bulk bags also possess the following benefits:

- Efficient use of space: These bags feature a unique design that allows them to be stacked efficiently, taking up less space compared to other packaging options.

- Versatility: Their versatility makes them an ideal choice for a range of industries, including agriculture, landscaping, and construction.

- Simple handling: Handling our baffle FIBCs is simple, as they can be easily lifted and moved using a forklift. They’re also designed with different loop constructions such as corner, cross, single & double stevedore, and sleeve lift.

- Cost-effective: Our solutions are designed to be the perfect size and shape to contain the goods they’re designed for. In addition, our manufacturing processes allow us to pass on cost savings to you, the customer.

- Customizable: In addition to choosing your preferred loop construction, you can also customize your product with a variety of top options, including open, duffle, and spout, as well as several bottom options, such as plain, standard discharge, conical discharge, flap, or duffle.

- Reusable & recyclable: We’re big advocates for avoiding single-use storage solutions, and our baffle bags are a testament to use. Designed to be used over and over again, they’re also completely recyclable.

Typical Uses For Our Baffle Bags

Baffle bulk bags are used to package and transport a wide variety of materials, including dry bulk goods such as grains, powders, seeds, and pellets.

They’re also particularly useful for products that are difficult to handle, such as fine powders that tend to settle and become compacted during transit.

Baffle bulk bags are also commonly used in the construction and landscaping industries to transport sand, gravel, and other aggregates.

Additionally, they’re suitable for use in the agricultural sector for packaging and transporting crops such as potatoes, onions, and garlic.

Don’t feel restricted to the above uses, though. We’re confident that we have a solution to suit your needs, even if it isn’t our baffle design.

Why Palmetto’s Baffle Bag?

We’re constantly reinvesting in our processes to deliver the most optimal bulk bag solutions to our customers:

In-House Design

Our graphics team offers a full range of services, including:

- Design assistance

- Concept development

- Layout

- Vectorizing

- Proofing

We work efficiently to provide quick turnaround times, allowing you to reduce the need for holding excessive inventory while minimizing our lead-times.

High-Quality Graphics

We offer high-definition print capabilities that ensure the most durable and precise graphics available, which is all thanks to our 10-color rotogravure press.

Our printing technology surpasses Mexographic printing, providing superior results that will meet your expectations.

Vertical Manufacturing

We’ve deliberately used vertical manufacturing to gain a strategic advantage in the advancement of our products and services.

In particular, our computerized vacuum-fed extruder produces a range of fabric styles, weights, designs, and performance levels.

In addition, our Starlinger looms with ultrasonic slitting, cutting-edge lamination, and specialized assembly departments ensure that we uphold top-quality production standards.

We meticulously craft your products from the initial sensor alignment on the tuber to the final inspection, ensuring the highest level of precision and attention to detail.

Custom Specs

Our vertical polypropylene manufacturing unit enables us to create custom 360-degree printed backseam fabric specifications, including:

- 1000 denier 80 gsm fabric containing 18-micron film gauge

- Regular 9x9 mesh

- Specialized micro-perforated circular weaves with EZ Open closure and an anti-skid treatment

We aren’t limited to the above specs, though. No matter what specification you need, get in contact with us today.

Contact Us

Baffle FIBC FAQs

What are baffle bulk bags, and how are they different from regular bulk bags?

Baffle bulk bags, also known as Q bags, feature internal baffles (panels) sewn into bags’ corners.

These baffles help to maintain the bags’ square shape, even when only partially filled, which makes them easier to stack and transport. Regular bulk bags don’t have internal baffles and are typically more flexible.

What are the benefits of using baffle bags over other packaging options?

Baffle bulk bags are more space-efficient than regular bulk bags, as their square shape allows them to be stacked more easily.

They also offer better stability and less product shifting during transport. Additionally, baffle bulk bags are often more cost-effective than other packaging options due to their space-saving properties.

How much weight can a baffle FIBC hold, and what are the size options?

Baffle bulk bags come in a range of sizes and weight capacities to suit different needs. The weight capacity can vary depending on the size of the bag, but our solutions are designed to hold up to 5,000lbs.

Can baffle bulk bags be reused, or are they intended for single use only?

Baffle bulk bags can be reused, which makes them a more sustainable packaging option than single-use bags.

However, the number of times a baffle bulk bag can be reused depends on factors such as the type of material it's used to transport, how it's handled, and how well it's maintained.

Baffle FIBC FAQs

What are baffle bulk bags, and how are they different from regular bulk bags?

Baffle bulk bags, also known as Q bags, feature internal baffles (panels) sewn into bags’ corners.

These baffles help to maintain the bags’ square shape, even when only partially filled, which makes them easier to stack and transport. Regular bulk bags don’t have internal baffles and are typically more flexible.

What are the benefits of using baffle bags over other packaging options?

Baffle bulk bags are more space-efficient than regular bulk bags, as their square shape allows them to be stacked more easily.

They also offer better stability and less product shifting during transport. Additionally, baffle bulk bags are often more cost-effective than other packaging options due to their space-saving properties.

How much weight can a baffle FIBC hold, and what are the size options?

Baffle bulk bags come in a range of sizes and weight capacities to suit different needs. The weight capacity can vary depending on the size of the bag, but our solutions are designed to hold up to 5,000lbs.

Can baffle bulk bags be reused, or are they intended for single use only?

Baffle bulk bags can be reused, which makes them a more sustainable packaging option than single-use bags.

However, the number of times a baffle bulk bag can be reused depends on factors such as the type of material it's used to transport, how it's handled, and how well it's maintained.